Understanding Conduit Bodies and Selecting the Right Type?

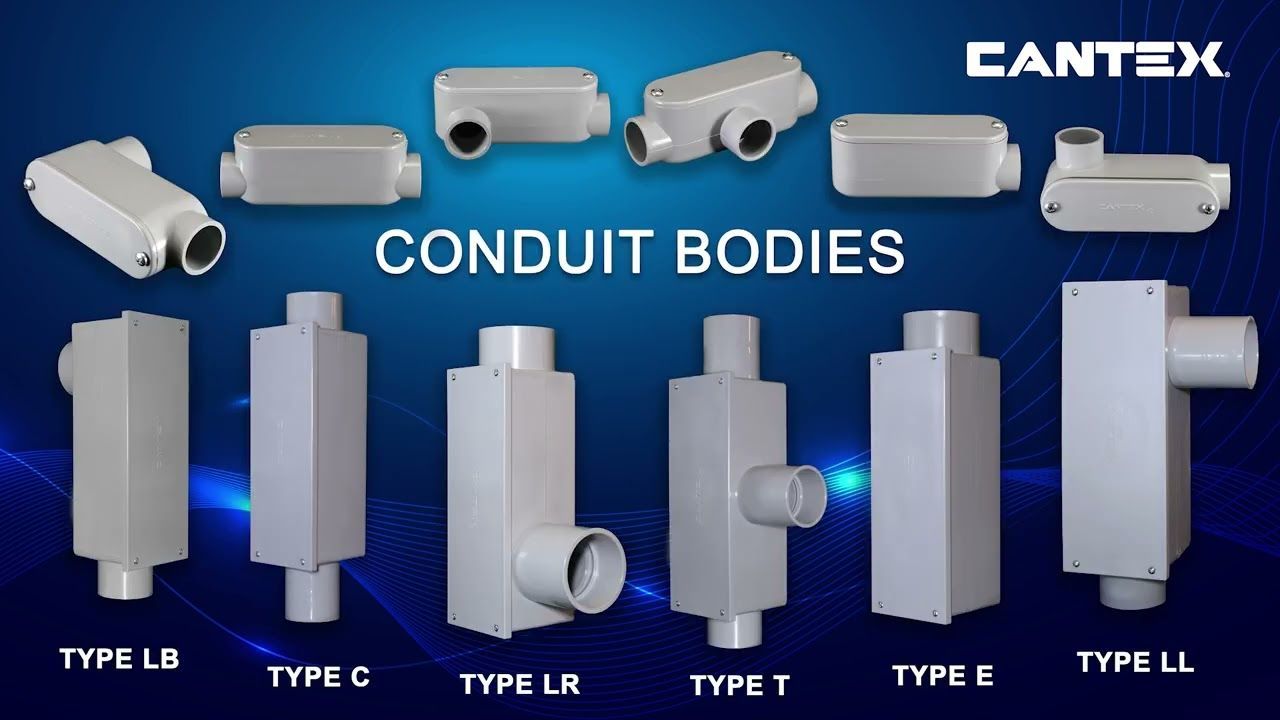

Mastering the knowledge of conduit bodies is a fundamental requirement for any professional engaged in electrical work. A conduit body, a type of fitting that facilitates a change in direction, grants access to conductors for maintenance and installation, or links conduit runs, is a cornerstone of electrical installations. These fittings, available in a variety of types such as LB, LL, LR, T, X, and Mogul, each tailored for specific applications and configurations, are the key to a safe and efficient electrical system. The art of selecting the correct conduit body is a mark of professional competence, ensuring the efficiency and safety of an electrical installation.

The LB conduit body, with a cover on the back side, is a versatile choice for a conduit run that changes direction from a horizontal to a vertical plane, especially in tight spaces. The LL and LR types, designed for left and right turns, respectively, offer flexibility in situations where space constraints dictate accessibility from specific sides. The LL conduit body, with a cover on the left side, and the LR, with a cover on the right, provide solutions for conduit runs that need to change direction.

The T conduit body, resembling the shape of a 'T,' is A solution for branching circuits, allowing three conduit runs to be connected at right angles. The X-type conduit body, shaped like an 'X,' is used when four conduit runs intersect, typically in complex wiring systems where multiple connections and changes in direction are necessary.

The Mogul conduit bodies might be required for larger or more complex installations. Mogul types are designed with a larger capacity to accommodate more conductors and provide greater access for pulling and splicing wires. These conduit fittings are ideal for industrial applications where heavy-duty requirements are prevalent.

When it comes to selecting the correct conduit body, the stakes are high. Factors such as the direction of the conduit runs, space constraints, the number of conductors, and accessibility for maintenance must be carefully considered. Each type of conduit body serves a specific purpose, and choosing the appropriate one is not just about efficiency, but also about ensuring that electrical installations are compliant with safety standards. By understanding the various types of conduit bodies—LB, LL, LR, T, X, and Mogul—electrical professionals can make informed decisions that enhance the functionality and safety of their conduit body projects, instilling a sense of confidence and security in their work.

Why material & environment matter

Conduit bodies come in a variety of materials — including PVC, galvanized steel, aluminum alloy, and stainless steel — and choosing the right one depends on where and how the conduit will be used. For example, PVC conduit bodies are lightweight and corrosion-resistant — a good option for outdoor or damp environments, while aluminum or stainless bodies offer durability and grounding continuity for rugged or industrial settings.

ledestube.com+1

Sizing & conductor capacity: avoid overcrowding

When selecting a conduit body, always confirm its internal cubic-inch volume versus the total cross-sectional area of all conductors inside. Overfilled conduit bodies can overheat, damage insulation, and violate inspection codes. For high conductor-count runs — or when you anticipate future additions — consider a “deep” or “Mogul” body to allow sufficient bend radius and space for safe wire pulling.

Installation best practices

- Match the hub type to your conduit: threaded hubs for rigid metal conduit or EMT, solvent-cemented smooth hubs for PVC runs. Mismatched hubs can cause leaks, wiring strain, or code violations. leaderful-tech.com+1

- For outdoor or wet location installations: use gasketed covers, corrosion-resistant materials (aluminum, stainless), and seal around cover edges to prevent moisture ingress.

- Leave easy access: screw-on covers should be positioned so they are reachable for future maintenance — never buried behind drywall or inaccessible surfaces.

- Never overfill. Follow manufacturer and code recommendations for minimum clearance and bend radius.

The conduit body is an essential component in electrical conduit systems, serving as a junction point for changing the direction of conduit runs or allowing for easy access to the wiring inside. This fitting is crucial for ensuring that electrical systems are secure and accessible for maintenance or modifications.

What's more, several types of conduit bodies are designed to accommodate different wiring pathways and installation requirements, showcasing their versatility. These include LB, LL, LR, T, X, and Mogul.

The LB-type conduit body is designed with an opening on the back side, which allows for a straight-through path of the conduit run. This type is frequently used where the conduit needs to change direction by 90 degrees.

The LL and LR types are similar in function but differ in the location of their openings; LL has its opening on the left side, whereas LR has it on the right side, making them suitable for different directional changes in the wiring layout.

The T-type conduit body features three openings in a T-shaped configuration, facilitating the branching of conduit runs. The X type has four openings at 90-degree intervals, making it ideal for use at intersections where multiple conduits meet.

For larger and more complex installations, the Mogul conduit body is utilized. It offers more space inside for wiring and is typically used in industrial settings where higher capacity and accessibility are required.

Each type of conduit body plays a critical role in electrical installations, ensuring that the conduit body system remains organized and functional while providing necessary access points for maintenance.

Understanding these types is not just beneficial, but empowering for electricians and installers. It helps them select the appropriate fittings for efficient and safe electrical system design, putting their knowledge and expertise to good use.

Conduit bodies are essential components in electrical conduit systems, serving as junctions for changing direction and providing access to electrical wires for maintenance and future upgrades. Different types of conduit body configurations are available to suit various installation requirements. Common conduit body types include LB, LL, LR, T, X, and Mogul. Each type offers unique benefits depending on the specific needs of the electrical system.

The LB-type conduit body is widely used for making 90-degree bends in conduit runs, featuring an opening on the back side for easy wire pulling. The LL and LR types are similar to the LB but with the opening on the left (LL) or right (LR) side, respectively. These configurations allow for flexibility in routing conduits around obstacles or fitting into tight spaces. The T-type conduit body has been designed for three-way intersections, enabling a straightforward connection for conduits from different directions.

The X-type conduit body is ideal for more complex intersections, providing a four-way junction that facilitates multiple conduit connections. This type is beneficial in applications where numerous circuits need to intersect at a single point. The Mogul conduit body stands out due to its larger size and capacity. It accommodates more significant conductors or provides additional space for wire splicing and pulling. Mogul types are often used in large industrial settings where higher capacity and accessibility are vital.

Selecting the appropriate conduit body type—be it LB, LL, LR, T, X, or Mogul—depends on the specific requirements of the electrical installation. Each conduit body type offers unique advantages that enhance the efficiency and functionality of the electrical system. Understanding these types ensures electricians can design and implement effective and reliable conduit systems tailored to their projects' needs.

LB Conduit Body: A type LB conduit body has an opening on the back and features two hubs forming an L shape. It is used to change direction at a 90-degree angle, often when routing electrical conduits from exterior walls into buildings.

LL Conduit Body: The LL conduit body has an access opening on the left side, allowing conductors to transition at a right-angle turn. This type is helpful when conduit runs must shift direction to the left.

LR Conduit Body: Similar to the LL but mirrored, the LR conduit body directs conduit runs 90 degrees to the right. The conduit body LR is commonly used where space is limited but wiring needs to change direction.

T Conduit Body (TB Conduit Body): This type has three conduit hubs in a T shape, allowing electrical wiring to branch into two different paths. The TB conduit body is ideal for circuit distribution.

X Conduit Body: With four hubs forming a cross shape, this body enables connections at a four-way junction, allowing conductors to be distributed in multiple directions.

C Conduit Body: The C conduit body is designed with two hubs in a straight line, offering easy access for wire pulling without altering conduit direction.

Mogul Conduit Body: This type has a larger interior space to accommodate multiple conductors and complex wiring configurations. The mogul conduit body is often used in industrial applications.

PVC Conduit Body: When corrosion resistance is a priority, a PVC conduit body is a great choice. These non-metallic bodies are lightweight, durable, and ideal for outdoor or wet locations.

How To Select The Correct Conduit Body

Effective conduit body selection depends on various factors, including the number of conduits, the necessary direction changes, and environmental conditions. If the goal is to transition between walls or make a 90-degree turn, an LB conduit body, LL conduit body, or LR conduit body would be the best choice. In contrast, a T conduit body (TB conduit body) or X conduit body is better suited for junctions where multiple conduits intersect.

Material is another key consideration in conduit body selection. Metallic conduit bodies, such as aluminum or steel, are durable for industrial settings, while a PVC conduit body is better for corrosive or damp environments. Furthermore, specialized bodies, like the mogul conduit body, provide additional space for larger wiring setups.

For scenarios that require a straight connection between conduits, the 1 1 2 LB conduit body or 1 2 LB conduit body is commonly used. Ensuring proper conduit body selection enhances safety and efficiency while maintaining compliance with electrical codes.

Conclusion

The right conduit body is essential for creating a well-organized and functional electrical system. Understanding different conduit body types and how they are used allows electricians to make informed choices. Whether it's a PVC conduit body, a TB conduit body, or a mogul conduit body, careful conduit body selection ensures longevity, reliability, and ease of maintenance.

Our Experience

At AC-DC Electric, we have been offering both residential, commercial & Industrial electrical services for over four decades. Our experience has taught us the best ways to perform various procedures. Our management and staff have seen electric systems evolve over time and have gained a deeper understanding of how they work. Thanks to our experience, we rarely encounter issues that we have never seen before.

Our knowledge

Each of our electricians and technicians is licensed, certified, and trained to provide high quality services. We understand the importance that electric systems play in both residential and commercial properties. This is why we handpick the best staff who are both knowledgeable and have demonstrated their ability in a variety of situations.

At AC-DC Electric, we foster an environment that encourages excellence. You can count on our electricians and technicians to get the job done with both speed and skill.

Our Transparent Pricing

Dealing with an electrical problem at home can be incredibly distressing, and many electricians and companies are willing to exploit people experiencing such issues by charging them high fees. At AC-DC Electric, we strive to provide high quality services at affordable rates. Our electricians’ specialize in Residential, Commercial & Industrial electrical services. We can also offer you a free estimate before you hire us. This ensures you remain aware of how much you will need to pay before using our electrical services.

If you’re ready to tackle your residential, commercial or Industrial property’s electrical problems quickly, please contact

AC-DC Electric

today. Our experts are always happy and ready to help residents in Fort Collins, Greeley, Evans, Johnstown, Loveland, Brighton, Commerce City and Denver Call today for a free estimate at 970-330-1656.

Resources:

AerosUSA - Conduit Body Types Explained

https://aerosusa.com/conduit-body-types-explained

Sonic Electric - Guide to Electrical Conduit Fittings

https://sonicelectric.com/blogs/news/a-guide-to-buying-all-types-of-electrical-conduit-fittings

IAEI Magazine - Conduit Bodies and Their Use in Accordance with the NEC

https://iaeimagazine.org/2006/january2006/conduit-bodies-and-their-use-in-accordance-with-the-nec

Consulting-Specifying Engineer - Selecting the Proper Wiring Solutions

https://www.csemag.com/articles/selecting-the-proper-wiring-solutions

Revco Electric - Conduit Bodies 101: Types & Applications

https://www.revcoelectric.com/roller/blog/entry/conduit-bodies-101-types-applications

What is a conduit body and why do I need one?

A conduit body is a small fitting that joins sections of conduit while providing access to the wires inside. It allows you to change direction (elbows), branch runs, pull or splice wires when installing or maintaining the system, without running a full junction box

What are the most common conduit-body types and when are they used?

Common types include:

LB — 90° turn with back access (great for wall-to-wall transitions).

acdc-electric.com

+1

LL / LR — 90° turns with side access (left or right), helpful in tight or offset spaces.

AerosUSA

+1

T — three-way junctions for branching circuits.

ledestube.com

+1

X — four-way intersections for complex multi-run systems.

acdc-electric.com

+1

C (Straight-through) — used when no bend is needed but access for pulling wires is desired.

ledestube.com

+1

Mogul / Deep-bodied — for large conduit runs, heavy-duty wiring, or when extra space is needed.

acdc-electric.com

+1

How do I choose the right material for a conduit body (PVC, metal, aluminum, stainless)?

Choose based on environment and code requirements:

PVC or corrosion-resistant plastic for damp, outdoor, or non-metallic environments

Galvanized steel or aluminum for indoor dry use when grounding continuity isn’t needed

Aluminum or stainless steel for industrial, wet, or corrosive environments where durability and grounding matter.

How many conductors can a conduit body hold?

That depends on the conduit-body’s internal volume (cubic-inch capacity) vs total volume of conductors (per NEC fill tables). For multiple wires or large gauge conductors you may need a “deep” or Mogul conduit body to maintain safe bend radius and comply with code.

Can I splice wires inside a conduit body?

Only if the conduit body is listed and rated for splicing. Many standard conduit bodies are intended only for conduit bends or pulling access — not as junction boxes. For splices, a properly rated junction box is usually required.

What happens if I overfill a conduit body with too many wires?

Overfilling reduces airflow, increases heat buildup, can damage insulation, create code violations — and increase fire or electrical-fault risk. Proper sizing prevents these hazards.

Is there a difference between a conduit body and a junction box?

Yes. A conduit body is mainly for changing direction or accessing conductors and is not always rated for splices. A junction box is designed for splicing, terminations, and generally has higher internal volume and code certification for wire splices.

Can I use any conduit body outdoors?

Only if it’s rated for outdoor/wet locations. For exterior or damp environments, choose a body with a gasketed cover and corrosion-resistant material (aluminum, stainless, PVC), and seal all entry points properly.

Do I need to match the conduit body hub type to the conduit (threaded vs PVC)?

Yes. Use threaded hubs for metal conduit (EMT, RMC, IMC); use smooth or solvent-cemented hubs for PVC conduit. Mismatching can cause leaks, poor mechanical integrity, and code violations.

Title or Question

Describe the item or answer the question so that site visitors who are interested get more information. You can emphasize this text with bullets, italics or bold, and add links.How often should conduit-body covers be inspected or maintained?

Check at installation and periodically (e.g., annually or after any environmental exposure). Ensure covers are tight, gaskets intact (for wet locations), and that the interior is dry and free of corrosion or debris.

Title or Question

Describe the item or answer the question so that site visitors who are interested get more information. You can emphasize this text with bullets, italics or bold, and add links.Are all conduit-body types allowed under the electrical code?

Most common types (LB, LL, LR, C, T) are permitted under standard conduit regulations — but code compliance depends on conduit type, conductor fill, environmental rating, and whether the body is listed or approved for the intended use. Some jurisdictions limit certain types (e.g. cross-type X in residential) — always check local code and inspector guidance.

Title or Question

Describe the item or answer the question so that site visitors who are interested get more information. You can emphasize this text with bullets, italics or bold, and add links.What size conduit body should I use for 3/4" EMT with four 12 AWG conductors?

You’d need a conduit body sized for at least the total conductor fill volume — check manufacturer’s cubic-inch rating. If wires are 12 AWG, and you have more than a couple conductors, a “deep” or “Mogul” body is often safer for pulling and code compliance.

Title or Question

Describe the item or answer the question so that site visitors who are interested get more information. You can emphasize this text with bullets, italics or bold, and add links.Can I mix PVC conduit with metal conduit bodies?

Yes — but only if the hub type matches (i.e. smooth/solvent cement hub for PVC). Mixing requires correct fittings and sealing; avoid mismatched hub types.

Title or Question

Describe the item or answer the question so that site visitors who are interested get more information. You can emphasize this text with bullets, italics or bold, and add links.What are common mistakes electricians or DIYers make with conduit bodies?

Overfilling, using the wrong material for environment, using threaded hubs on PVC conduit (or vice versa), burying covers behind drywall, failing to gasket or seal for outdoor use, ignoring code fill requirements.

Title or Question

Describe the item or answer the question so that site visitors who are interested get more information. You can emphasize this text with bullets, italics or bold, and add links.When should I consider a “deep” or “Mogul” conduit body instead of a standard one?

When: you have large conductors, many conductors, expect future expansion, need splicing access, or have limited bend radius space. Deep bodies give more cubic-inch capacity and make wire pulling much easier and safer.

Does the conduit body help protect against moisture or corrosion?

Only if the body is made of corrosion-resistant material (aluminum, stainless, PVC) and properly sealed (gasketed cover). Otherwise, moisture and corrosion can degrade conductors over time.

Can I use conduit bodies for low-voltage or data cabling too?

Yes — conduit bodies protect and organize any conductors inside a conduit run. For data or low-voltage wiring, choose appropriate materials and follow fill rules and separation from high-voltage circuits as required by code.

Title or Question

Describe the item or answer the question so that site visitors who are interested get more information. You can emphasize this text with bullets, italics or bold, and add links.What is the difference between a conduit body and conduit bending?

Conduit bending uses sweeps (curved bends) instead of fittings to change direction; conduit bodies use rigid fittings providing access and pull points. Bodies are helpful when bends would be tight, wiring runs complex, or future access is needed — and often required by code when bend radius or number of bends exceed limits.

Do I need a permit to install conduit bodies in a residential project?

That depends on your local building / electrical code. Many jurisdictions require permits for conduit installations (especially when adding or modifying circuits), especially if part of a remodel or new installation. Always check local code or consult a licensed electrician.

Title or Question

Describe the item or answer the question so that site visitors who are interested get more information. You can emphasize this text with bullets, italics or bold, and add links.What happens if I choose the wrong conduit body type for a job?

You risk code violations, damaged wiring, difficulty pulling wires, future maintenance problems, moisture ingress (if outdoor), potential overheating, and failed inspections. In worst cases — electrical shorts or fire hazards.

You might also like