How to use a Wire Stripping & Twisting Tool

Tools and tricks to help you master the basics of how to strip wire using Wire stripping & Twisting Tool.

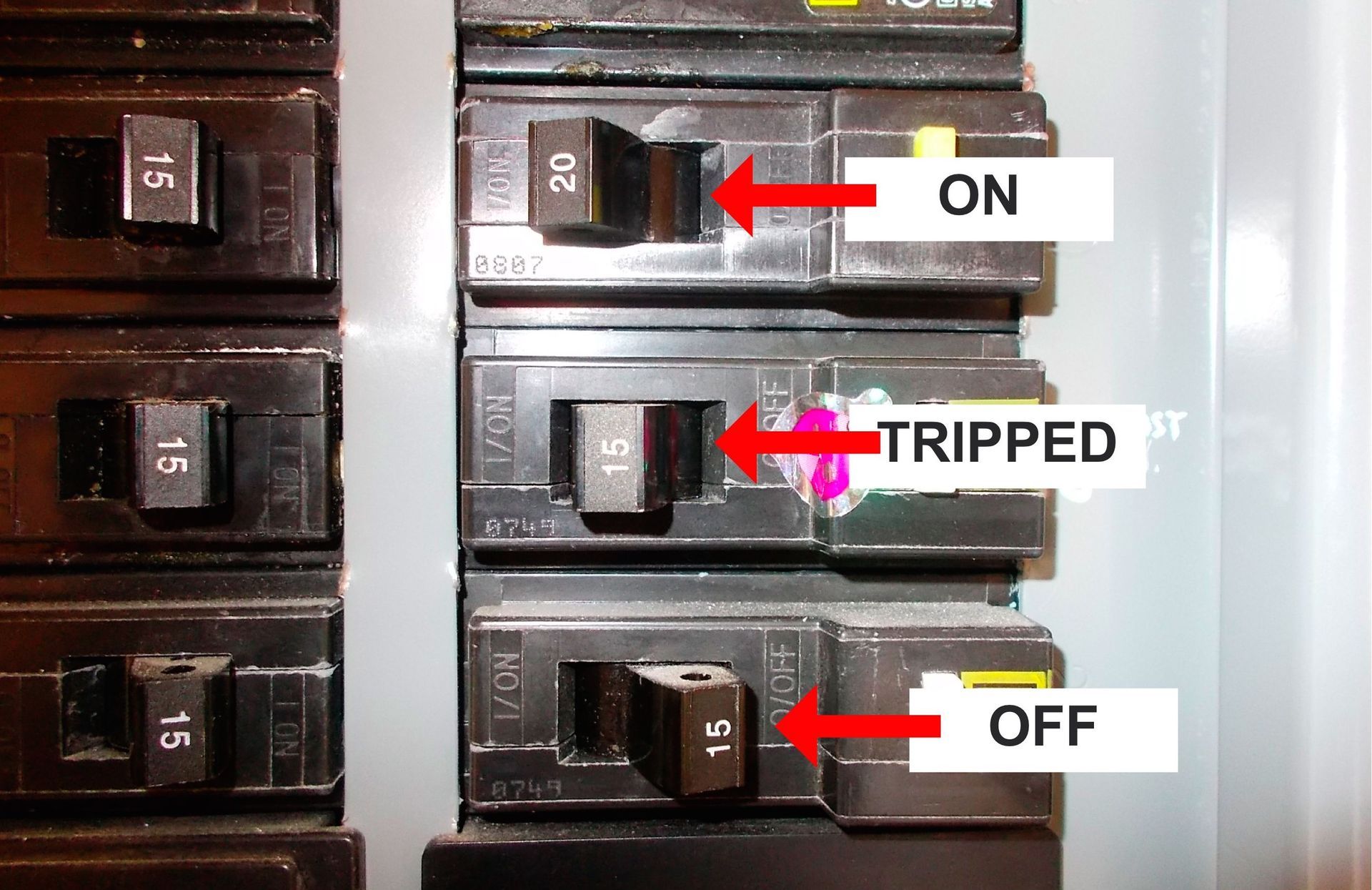

“Safety First (Before You Start)”

Add the following content:

- Always switch off and test for power before handling any wires

- Wear safety glasses and work gloves

- Work on a dry surface

- Never strip wires when energized

- Avoid working near water, damp areas, or frayed conductors

Wire Stripping & Twisting Tool Tools and tricks to help you master the basics of how to strip wire using Wire stripping & Twisting Tool.

With special tools and techniques for stripping any kind of wire. Different types of electrical cable and cords, coaxial cable, communication wires and thin phone and bell wire are all covered.

Always call a professional for any issues, frayed wires, breaker issues, etc. www.acdc-electric.com

How to Strip Wire

Safe, durable electrical connections begin with clean, accurate wire stripping. You have to remove the outer layer of plastic without nicking or slicing the insulation or wires underneath; otherwise, your connection might break or an electrical short might occur.

In a pinch, you can strip almost any wire or cable with nothing more than a sharp pocketknife or utility knife. We will show you how to strip wire safely and carefully. But for fast, accurate stripping, we recommend the specialized stripping tools we demonstrate in this article. They are affordable and easy to use, and they produce high-quality results. Be sure to select the wire stripper labeled for the type of wire you are working with.

All the tools we show are available at home centers and electrical supply stores. Buy each as you need it, and you will soon have exactly what you need for any home wiring task.

How to Strip Wire Without Wire Strippers

If you don’t have a specialty tool for the job, don’t despair you can still figure out how to strip wire as long as you have an implement sharp enough to cut the sheathing, like a utility knife, a pair of scissors, or even a sharp pocket knife. The process is similar but takes a little more practice to get just the right touch—enough pressure to cut off the sheathing without damaging the actual metal wires.

How to Strip Wire: Electrical cords

Score a circle around the cable jacket, but do not cut all the way through the plastic. This technique may look dangerous, but it is safe if you apply very light pressure with the knife and keep your thumb on the opposite side of the cord. Carefully guide the knife around the cable until you reach your starting point.

A knife works best for stripping sheathing from cords. It takes a sharp blade, a steady hand, and concentration to control the depth of the cut precisely. But once you master the technique, you’ll be surprised how quickly and accurately you can remove cord sheathing.

We are showing the technique on a cord, but it also works on a plastic-sheathed cable. Practice with the blade extended or barely visible to see which technique works best for you.

When it comes to stripping individual wires, a wire stripping tool is faster and more accurate, but in a pinch, you can use a knife with all these techniques, the key is to control the depth of the cut to avoid cutting or gouging the conductor.

Plastic-sheathed cable

Align the plastic-sheathed cable with the notch that matches the wire gauge you’re using—either 14/2 or 12/2—and squeeze down to cut the sheathing. Slide the sheathing off to expose the wires underneath.

Stripping plastic-sheathed (NM, for nonmetallic) type cable is a two-step process. First you remove the outer plastic sheathing. Then you strip the individual conductors. There are many methods to remove the plastic sheath, ranging from a simple knife technique to special tools. The stripping tool we’re using is unique because it combines both sheathing removal and wiring stripping in one tool and works perfectly for both tasks. It’s well worth the price if you do any amount of home wiring. Otherwise, buy a less expensive, general-purpose stripper and use a knife or other method to remove the outer sheathing.

Test cutter depth on a cable scrap. Adjust the two cutting blades one at a time to fine-tune the cut depth. Turn the adjusting screws clockwise with the Allen wrench (included with the tool) to make a deeper cut.

Adding F-type connectors to coaxial cable requires a two- or three-step stripping on the cable end, depending on the connector. With care, you can make the strip with a utility knife, using the technique shown in Photo 1 and a regular wire stripper. But the dedicated tool we show here makes the job quick and accurate. Read the packaging to match the stripper to the type of coaxial cable you’re using. The strippers you find in home centers work on common household coaxial cables.

Read the lettering on the sheathing to determine whether your coaxial cable is RG-58, RG-59 or RG-6, and adjust the slide on top of the cutter to match your cable type. Make a practice cut and adjust the blades if necessary.

Cable stripper

Use a cable stripper tool to remove the sheathing from communication wires.

With high-speed Internet lines and household computer networking becoming more common, you may soon find yourself installing new communication cables capable of handling higher bandwidths. Here’s an inexpensive tool that makes short work of removing the outer sheath from these small cables without nicking the conductors inside. The cable size notches aren’t labeled, so you’ll have to experiment to find the one that works.

Features of Combination Wire Strippers & Twisting Tool

Combination wire tools, or combination wire strippers, are multi-function tools with sharp cutting jaws for cutting non-metallic (NM) cable or trimming individual wires to size. They may also have pliers’ jaws for bending wires. The same jaws may also be used to ream the inside of metal conduit after it is cut, using the outsides of the jaws when they are in the closed position.

Most combination strippers also have two different holes for cutting machine bolts, usually 6-32 and 8-32 sizes. You thread a bolt into the hole to the desired depth, then squeeze the tool's handles to cut off the bolt's end. When you twist the bolt out of the hole, the threads in the hole realign the threads on the cut end of the bolt.

Self-Stripping Tools

Another type of wire stripper is a self-stripping tool, or self-adjusting wire strippers, that removes wire insulation with a compound action. This means that three actions take place when you squeeze the handle: grip, strip, and remove. After you precisely place the wire in the head and squeeze the handle, the stripper grabs the wire, cuts the insulation, and completely removes it, all in one motion. Self-stripping wire strippers are about three times more expensive than normal strippers. They serve only one function and are normally owned by professional electricians who prefer specialty tools for each task.

Wire Stripping & Twisting Tool

- Brand: Neepanda Wire Twisting Tool

- SPECIFICATIONS

- Material: Steel

- Weight:0.24lb

- Suitable:for Power Drill Drivers

- Package Include:1 x Wire twisting tool

Product Features:

Wire Stripper and Twister tool made of high quality high speed steel with good performance and high precision.

The operation is very simple, allowing you to turn the wire quickly and beautifully.

Steps:

Install the Wire Stripper and Twister on the hand drill chuck and clamp it (note: the drill must confirm clockwise rotation).

Pass the wires to be connected in the wire hole and try to keep the cables through the hole to the same level.

Clamp all the wires with a wire cutter and keep the pliers and the Wire Twisting Tool as close as possible.

Start the electric drill, the speed of the electric drill can't be too fast, the starting electric drill must not pull back, but push it slightly in the direction of the pliers.

Note:

All dimensions are measured manually and there may be small deviations.

The first time you use the Wire Stripper, you may not have a good twisting effect. You can practice using some old wires.

We are always available to take a look at your project and offer advice – www.acdc-electric.com

“Wire Gauge / Tool Setting Guide”

Example table:

Wire Type Common Gauge Tool Setting / Notch Solid Copper (House Wire)12–14 AWG Match AWG notch Stranded Hook-up Wire, 16–20 AWG Slightly smaller notch than printed NM Cable (Romex)12/2, 14/2Use cable sheath cutter first, then inner wire notch Coaxial Cable RG-6, RG-59Use coax-specific cutter (not standard strippers)

“Common Problems & How to Fix Them”

Include items such as:

- Conductor gets nicked — use a larger notch; apply less pressure

- Insulation won’t slide off — rotate the tool once, pull firmly

- Twist is uneven — reduce drill speed; hold wires together more tightly

- Insulation strips too deeply — switch notches; do not squeeze hard

Wire Stripping Tools-FAQ's

How do I know which notch or setting to use on the tool?

Look at the wire’s insulation markings (gauge or cable type), then choose the notch on your tool that matches that gauge. If the tool is unlabeled, start with a mid-sized notch and test on scrap wire. The insulation should be cut cleanly — not gouging or nicking the conductor.

toolsadvisers.com

How much wire insulation should I remove before twisting or connecting?

Usually around ½ to 1 inch (about 12–25 mm) of insulation is removed — enough to have sufficient exposed conductor for a secure twist/connection

Can I use a knife instead of a stripping tool?

In a pinch you can — but it’s riskier. A knife requires a steady hand and precise control to avoid cutting the conductor. A proper wire-stripping tool is far safer, faster, and cleaner.

What if the insulation won’t come off or I nicked the copper wire?

Stop, inspect the wire — nicked conductors can lead to weak or unsafe connections. Try again on scrap wire with gentler pressure or a different notch. If insulation is stubborn, a different tool or method may be necessary.

Is a drill-powered twisting tool safe and reliable?

Yes — but only if used properly. Use low drill speed, keep pressure even, hold the wires and pliers close, and make sure the drill’s rotation direction is correct. For first-time users, practice on scrap wiring before doing real work.

When should I hire a professional instead of doing it myself?

If wiring involves high-voltage, main service panels, complex multi-strand or specialty cables, or if you’re unsure about local electrical code — hire a qualified electrician. Mistakes can lead to serious hazards.

How do I maintain my stripping/twisting tool so it lasts long?

Clean off insulation debris after each use, wipe down blades/jaws, store in a dry place, and inspect regularly for dullness or damage. Replace or sharpen blades if needed. Proper maintenance helps ensure safety and clean cuts.

You might also like